-

Inside the Selkirk Lab: How a CT scanner helps ensure paddle durability and quality

The following information was provided by one of our engineers during a break from the lab. Selkirk engineers take paddle performance and durability seriously, and to help aid in testing, the Selkirk Lab members use a piece of equipment that is rare to the pickleball world: an industrial CT scanner. Although CT scanners are more commonly associated with hospitals or advanced aerospace research labs,... -

Inside the Lab: How 3D printing enhances pickleball paddle design

The following information was provided by one of our engineers during a break from the lab. In the Selkirk Lab, engineers leverage additive manufacturing — commonly known as 3D printing — to aid the pickleball paddle development process. This technology enables engineers to rapidly prototype paddles and their components, allowing for extensive experimentation with various shapes, ergonomics, and performance characteristics before committing to full-scale... -

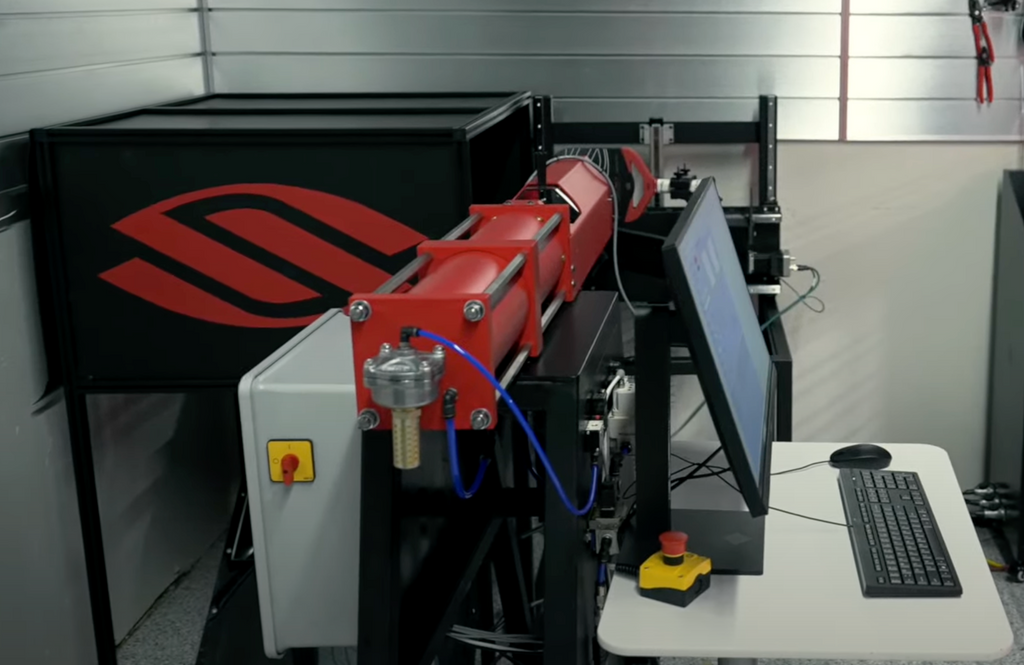

Inside the Selkirk Lab: How Selkirk uses a performance cannon to test paddle power and spin

The following information was provided by one of Selkirk’s engineers during a brief break from work in the Selkirk Lab. Selkirk Sport engineers take testing seriously — not just to meet industry standards but to advance paddle technology. One of the most sophisticated tools used in the Selkirk Lab is the performance cannon, a machine designed to quantify paddle power and spin under highly...

Close

Sign In

Close

Your Cart

Your cart is currently empty.

Total

Shipping

Taxes and shipping fee will be calculated at checkout

Selkirk recognizes the sacrifices made by our military/first responders. Log in here for details.